Soft enamel pin construction

Once the plating is ready, there are three steps to completing a soft enamel pin.1. Electroplating or dying the plating

Electroplating is the process of adding an outer layer of metal, like gold or silver, to the pin’s base of iron or zinc alloy. The plating can also be dyed with a color at this stage.

2. Enameling

The next step is to put liquefied colored enamel in the cavities of the metal base. In soft enamel pins, each cavity is only partially filled. That’s why you can feel the raised metal edges in soft enamel pins.

In this wizardly little example, the silver plating is raised, forming both the outer edge of the pin as well as some of the design elements. The colored enamel is recessed.

3. Baking

Finally, the pin gets placed in an oven and baked to set the enamel.

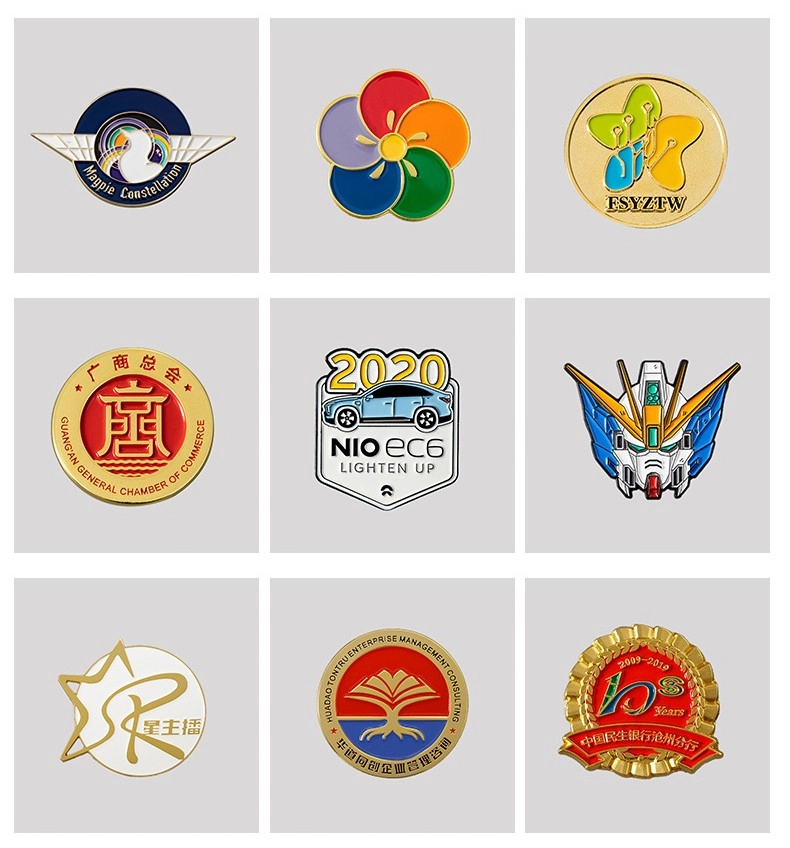

Specification

- Material : Zinc alloy

- Plating Process : Gold, Silver, Bronze, Nickel, Copper, Rhodium, Chrome, Black Nickel, Dyeing black, Antique Gold, Antique Silver, Antique Copper, Satin Gold, Satin silver, dye colors, dual plating color

- Size : Custom made. According to customer's requirements.

- Shape : Custom made. According to customer's requirements.

Order Information

- Minimum order quantity : 100pcs per design.

- Standard Packing : Individual OPP Bag

- Optional Packing : Individual Gift box, printed card

- Delivery : Need to confirm upon artwork or sample approved.

- Lead Time : 14 - 20 working days. lead time is negotiable.

Inquiry - Custom made Soft Enamel Pin